Tech Juice 2507: AI-enabled Digital Twins & Predictive Maintenance

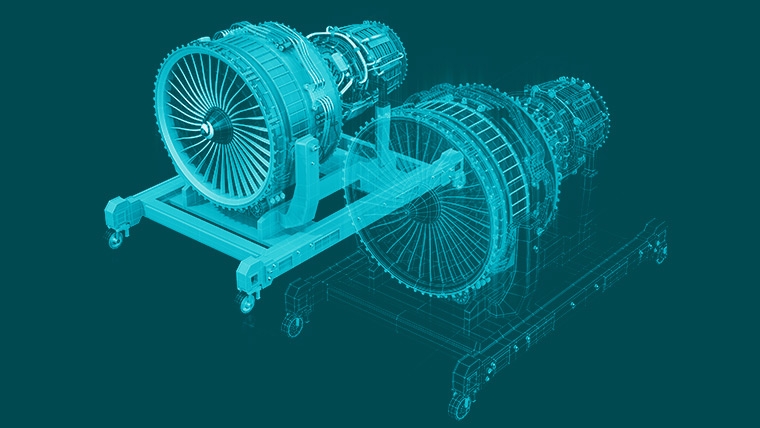

How AI-Enabled Digital Twins Will Revolutionize Predictive Maintenance

AI-enabled digital twins have the potential to revolutionize predictive maintenance in several key ways:

Real-time Monitoring and Data Integration: A digital twin is a virtual representation of a physical asset, and when enhanced with AI, it can continuously integrate data from sensors and IoT devices. This allows organizations to monitor the health and performance of equipment in real-time, providing a comprehensive view of its operation.

Predictive Insights: AI algorithms can analyze historical and real-time data from the digital twin to detect patterns and predict potential failures before they occur. This predictive capability is more accurate than traditional time-based maintenance schedules and can reduce the risk of unplanned downtime.

Anomaly Detection: AI-enabled digital twins can automatically detect anomalies in the behavior of equipment, even subtle deviations from normal operating conditions. By comparing the virtual twin with the real asset's performance, AI can identify early signs of wear and tear, vibration issues, or inefficiencies, allowing for timely interventions.

Optimization of Maintenance Schedules: Traditional maintenance schedules are often based on fixed intervals, regardless of an asset's actual condition. With AI-enabled digital twins, maintenance can be scheduled based on actual usage patterns and condition monitoring, optimizing maintenance resources and reducing unnecessary work.

Scenario Simulation: AI-enabled digital twins can simulate different operating conditions and stress tests to forecast the impact of various factors on asset performance. This allows for better planning and preventive actions by testing potential failure scenarios virtually before they happen in real life.

Cost Reduction: By reducing the likelihood of unexpected breakdowns, AI-driven digital twins can minimize costly downtime and extend the lifespan of assets. This leads to more efficient use of resources and a reduction in emergency repairs, lowering overall maintenance costs.

Continuous Learning: AI can continuously improve its models by learning from new data and experiences. As more data from the digital twin is collected, AI can refine its predictive models, making maintenance predictions more precise over time.

Improved Decision-Making: With the insights provided by AI-driven digital twins, maintenance teams can make data-driven decisions, improving resource allocation and ensuring that repairs are done at the right time, minimizing downtime and maximizing asset availability.

AI-enabled digital twins represent a significant leap forward in predictive maintenance, enabling organizations to move from reactive maintenance to proactive, data-driven decision-making. This not only reduces costs and improves efficiency but also enhances the reliability and safety of critical assets.

Great idea

ReplyDelete