Tech Juice 2510: Impact of Industry 4.0 Technologies on Industrial Materials

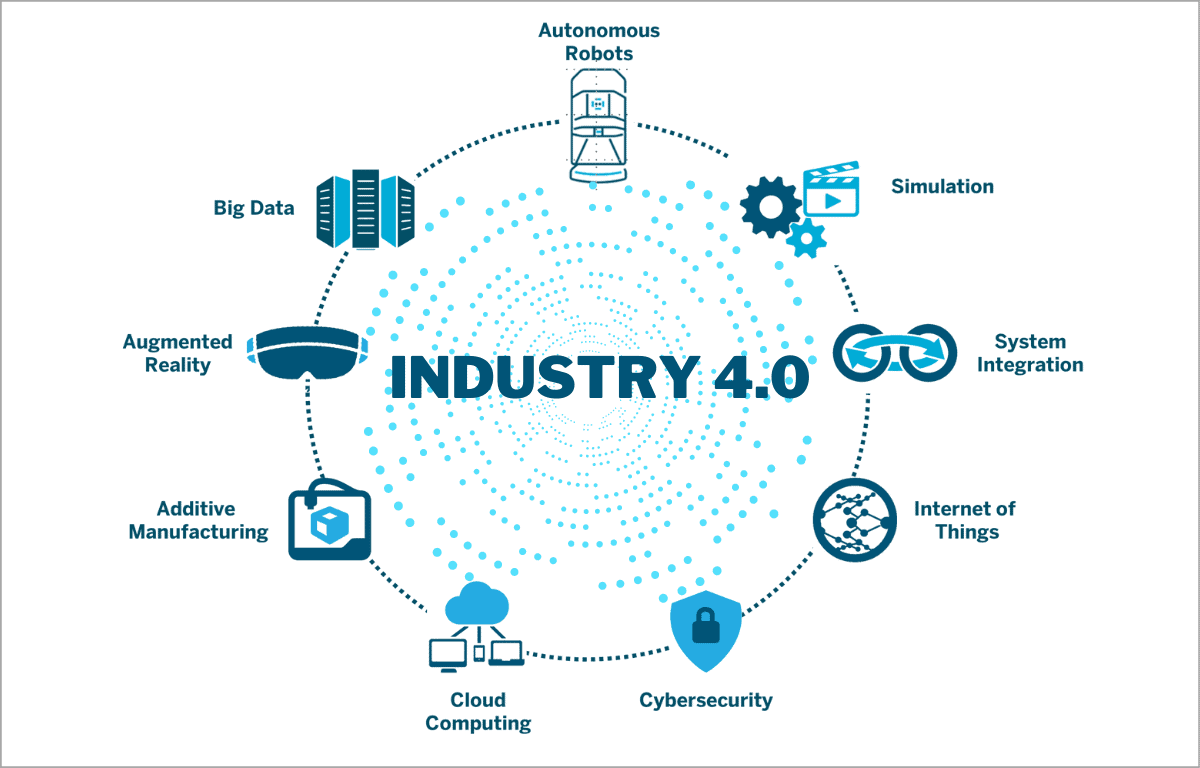

1. Industry 4.0 is the new version of an industry that has emerged through the influence of technologies such as Artificial Intelligence (Machine learning), the Internet of Things (IoT), additive manufacturing (3D printing), Robotics, Digital Twins, etc. The impact of these technologies on material science has been immense. Their ability to estimate, learn, simulate and build entirely from a knowledge base has transformed the industry's ability to discover new materials, deploy them on applications, monitor their performance through a lifecycle and update learning to repeat this cycle better than before is truly a major impact.

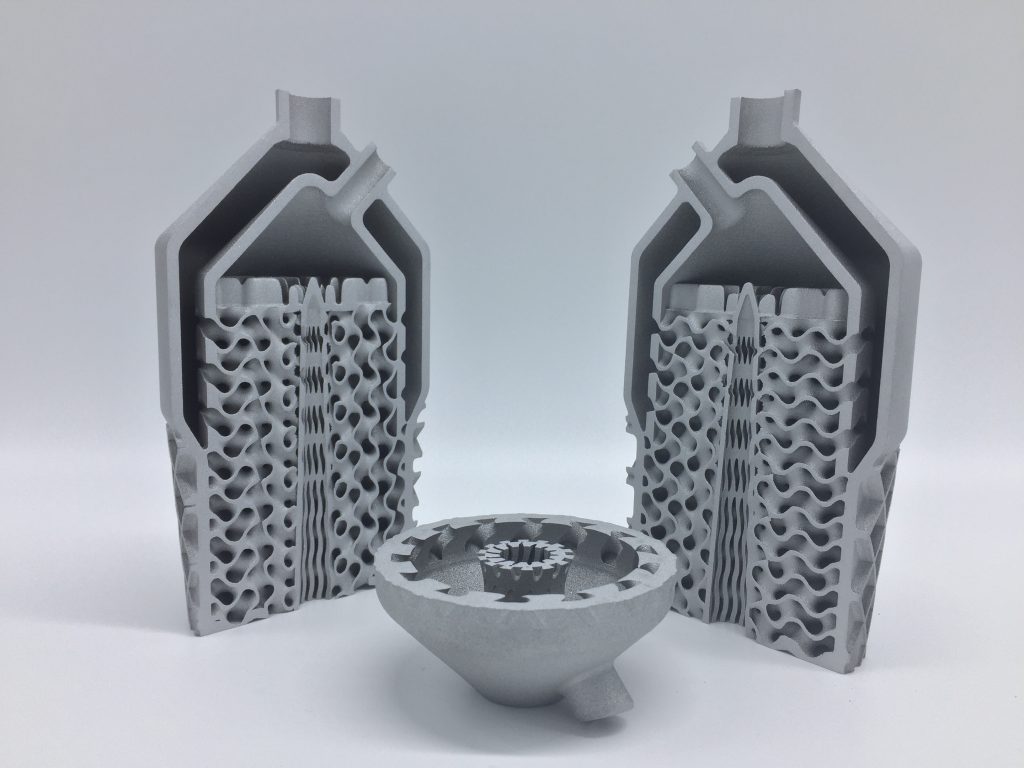

Accelerated Advanced Material Development

2. For example, traditional aluminium alloys (Al7075/Al6061) are unsuitable for 3D printing as they are prone to cracking. Boeing used the magic of AI, Machine Learning, Big data, modelling, and simulation to accelerate the development of HRL Laboratories' HRL7A77 aluminium alloy. This advanced alloy can be 3D printed to create complex parts, eliminating assemblies and reducing weight for aircraft, spacecraft, and even hypersonic vehicles. Without IR4.0 technologies, this development would have required years of costly physical testing. 3D printing of most parts can revolutionise supply chains by ensuring on-demand localised printing of parts, reducing inventory, and enhancing availability. Customisation of parts, even when parts are not interchangeable can be achieved.

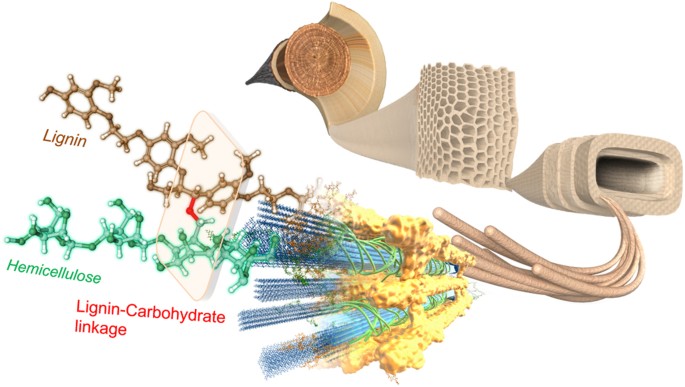

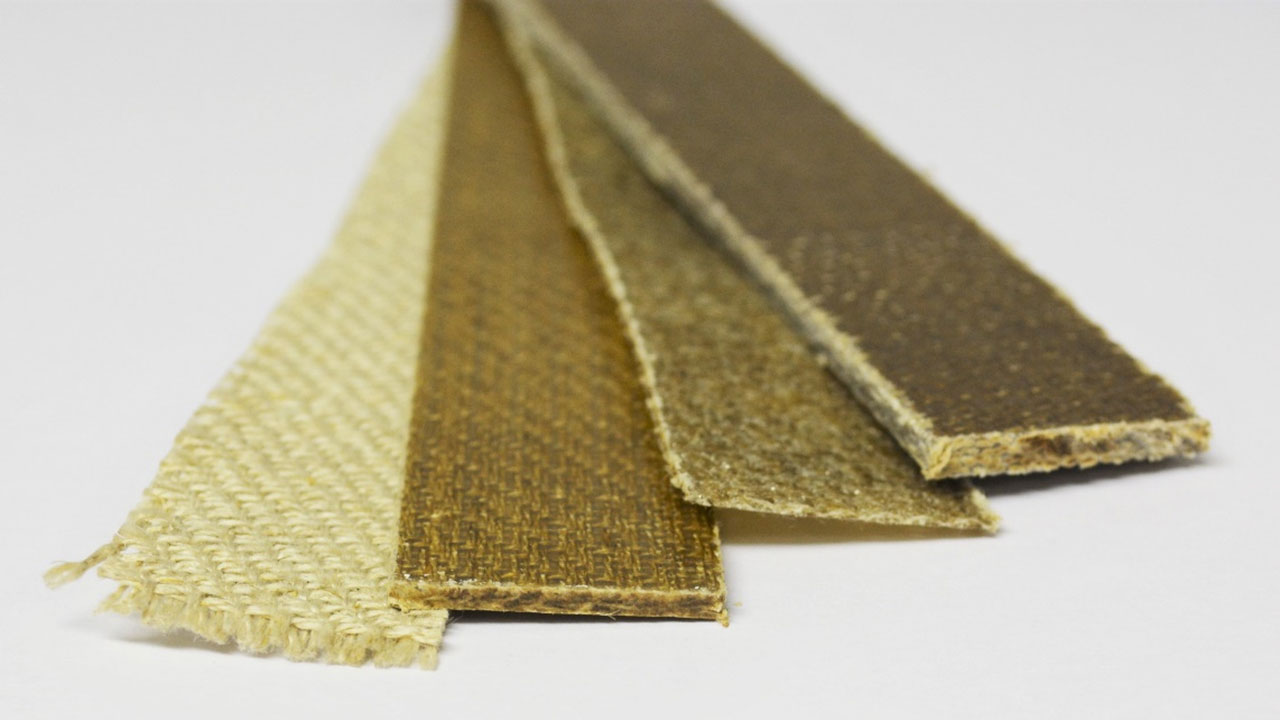

3. Lignin is a natural polymer found in plants. Lignin-derived bio-based carbon fibre composites are being developed to replace the petroleum-based carbon fibre composites presently being used to build aircraft structures.

Smart Sensors and Predictive Maintenance

4. There is an old joke that when an aerospace company is excavated by advanced humans 1000 years from now, they will think that it was a paper factory, which also was so rich that it owned a few aircraft!!! Certifying new materials for use on aircraft can be cost prohibitive, but for the new methods of development, which also provide proof of performance through modelling and simulation.

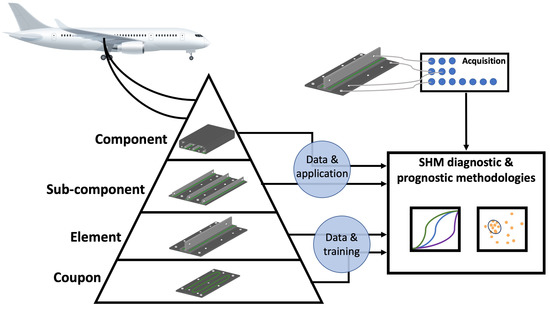

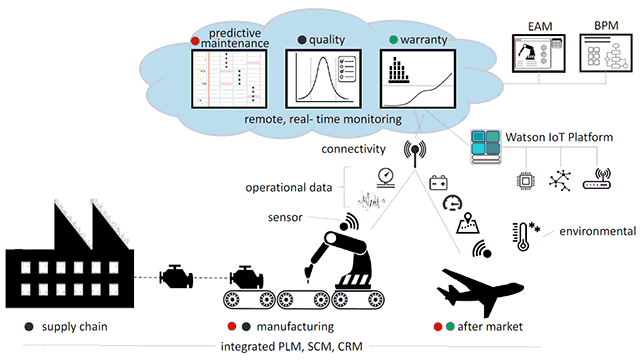

5. Smart sensors are those that not only collect data but also process and transmit the data in real time from the place of use to a cloud service. This data can then be used to refine a digital twin to both confirm satisfactory performance and to suggest a maintenance intervention, if necessary. Smart sensors could be fibre optic, piezoelectric, acoustic, thermally sensitive, etc.

6. The Airbus A350XWB uses advanced materials (composites and advanced aluminium alloys) for its fuselage and wing structures. These structures have embedded fibre-optic smart sensors to monitor stress, strain, and temperature in real-time. Data from these sensors is transmitted to the cloud in real-time. AI/ML and digital twin algorithms process this data and predict early signs of fatigue, material degradation, or cracks. This dramatically improves the aircraft's availability and the safety of its operations through achieving truly predictive maintenance.

7. The Traceability of materials used is vital for certifying safety-sensitive structures and parts. Blockchain technologies, born out of advanced cryptographic techniques, can be used to trace the entire supply chain, eliminating material fraud and providing complete supply chain transparency. These technologies can be effectively integrated with IoT technologies to provide excellent tracking abilities of the supply chains.

Technology Challenges Triggered by Climate Change

8. Climate change has demanded a complete relook at the mine-produce-use-throw economy. There is an increasing demand for a circular economy, minimising the need to continually mine and address the issue of waste management. One research program that focuses on reducing the environmental impact of aviation is CleanSky2. The primary objectives of CleanSky2 are to reduce carbon dioxide emissions by 20-30%, nitrogen dioxide emissions by 40%, aircraft noise levels by 20-30% and develop innovative technologies in materials, hybrid-propulsion and aerodynamic efficiency. All of the objectives of CleanSky2 also depend on the rapid development of new materials using IR4.0 technologies. These new materials when coupled with automation and robotics in manufacturing can truly enable green manufacturing.

![Clean Sky 2 key demonstrators [Source: www.clean-aviation.eu].](https://www.researchgate.net/publication/372007216/figure/fig1/AS:11431281171862657@1688387331123/Clean-Sky-2-key-demonstrators-Source-wwwclean-aviationeu.png)

9. Promising trends include the development of bio-based carbon fibre composites for lightweight, fuel-efficient aircraft, flax fibre composites, and self-healing polymers. Flax fibres, derived from plants, are used as a natural alternative to synthetic carbon or glass fibres in composite materials. Flax fibre composites have been tested for lightweight aircraft interiors, UAV structures, and non-load-bearing panels, improving their eco-friendliness.

10. Technologies that enable the recovery and recycling of carbon fibre parts focus on separating the resin used to bind the fibre through either pyrolysis (High-temperature thermal decomposition of the resin) or Solvolysis (Using Solvents and Catalysts at lower temperatures to separate the fibre). Pyrolysis is an industrial-scale process that has the disadvantage of releasing volatile organic compounds requiring gas treatment systems. Solvolyis is a more advanced process that does not damage the fibres but is not yet scalable. Accelerated process design using IR4.0 technologies is a promising route to quickly scale the solvolysis process and enhance our ability to recycle old CFRP aircraft parts, making aviation a little greener.

11. Self-healing materials have the capability to greatly enhance the life of aircraft structures. Composite materials infused with microcapsules containing healing agents (like epoxy resins) have been developed that automatically repair cracks when damage occurs. These can be used in aircraft fuselages and wings to repair minor damage and prevent crack propagation. NASA and the University of Bristol have developed these for aerospace applications. This development has the potential to drastically improve the life span of aircraft structures.

Nano Technology Integration

12. Nanotechnology integration enables materials at the molecular or atomic level to be engineered for enhanced strength, durability and functionality. This leads to lighter, stronger, more heat-resistant and self-healing materials. For example, Carbon Nanotube Composites are 100x stronger than steel but lighter. Graphene-reinforced polymers make composites stronger, stiffer, and more conductive, reducing weight while increasing durability. Nano-ceramic coatings can protect jet engines, hypersonic vehicles and spacecraft from extreme temperatures. Ultra-high-temperature ceramics and metal matrix composites are highly heat resistant and find applications in spacecraft re-entry and hypersonic applications. As mentioned before, nano-encapsulated healing agents (i.e. polymers with embedded micro/nanocapsules) release healing agents when cracks form. Super-hydrophobic nanocoatings can prevent ice formation on aircraft wings and windshields. Nano-coated alloys can improve corrosion resistance in salt-heavy environments (i.e. coastal and naval applications). Nano-lubricants can reduce friction in engines and improve efficiency. Nanowire sensors can enable lightweight and flexible electronic circuits for aircraft health monitoring. Rapid prototyping, testing and production of these products need AI/ML, automation and other Industry 4.0 technologies.

Conclusion

13. Overall, Industry 4.0 technologies are revolutionising industrial materials by making them smarter, more efficient, and more sustainable. They are specifically transforming aerospace materials by enhancing performance, reducing weight, improving sustainability, and optimising manufacturing processes.

Comments

Post a Comment