Tech Juice 2502 - The Role Of Robotics in Industrial Revolution 4.0?

- Get link

- X

- Other Apps

03 Dec 24

Motivation: Will countries with young populations loose out to Robots?

The role of robotics in Industry 4.0 (the Fourth Industrial Revolution) is fundamental and transformative, driving a significant shift in manufacturing, production processes, and business operations. Industry 4.0 is characterized by the integration of advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), machine learning, and big data, with cyber-physical systems (CPS) to create highly automated, efficient, and flexible systems.

Robotics plays several crucial roles in this revolution:

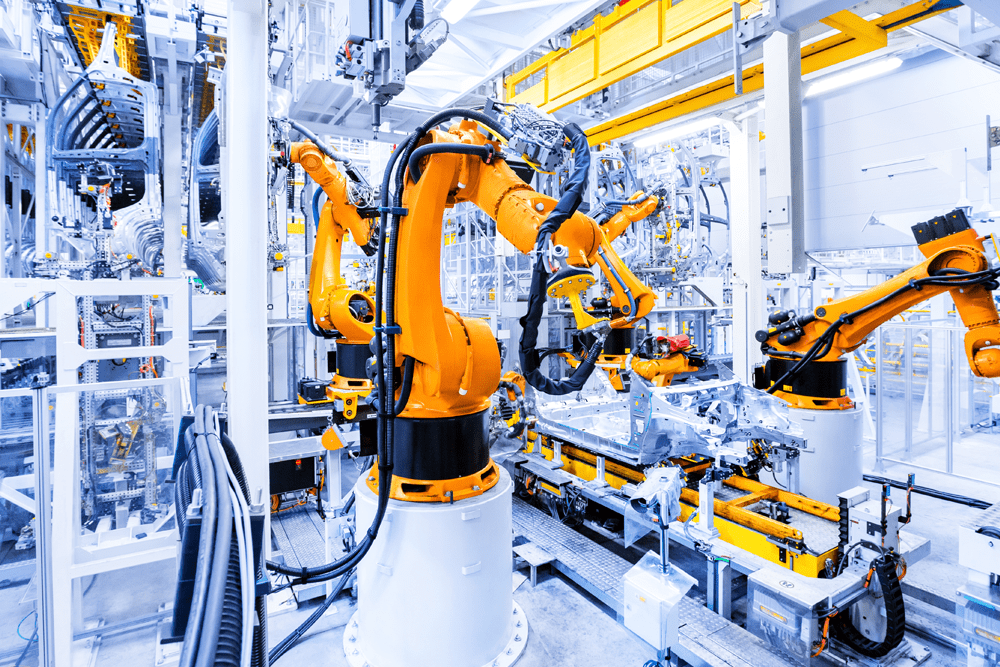

1. Automation of Repetitive Tasks

Robots are used to automate routine and repetitive tasks in manufacturing and production lines. This reduces the need for human intervention, speeds up processes, and ensures precision. Tasks like assembly, welding, packaging, and painting, which were once performed by humans, are now handled by robots, leading to greater efficiency and quality.

2. Collaboration with Humans (Cobots)

In Industry 4.0, the integration of collaborative robots (cobots) is a key feature. Unlike traditional robots that operate independently, cobots are designed to work alongside humans safely and effectively. These robots assist human workers by performing heavy or precise tasks, allowing human employees to focus on higher-level decision-making and problem-solving activities.

3. Real-Time Data and Decision-Making

Robots in Industry 4.0 are not just automated machines; they are often equipped with sensors and connected to IoT systems that enable them to collect and transmit data in real time. This data can be analyzed to optimize production processes, predict maintenance needs, and make adjustments on the fly to improve efficiency. Robotics systems powered by AI and machine learning can also learn from this data to enhance their performance over time.

4. Flexibility and Customization

Industry 4.0 introduces the concept of mass customization in manufacturing. Robotics allows for highly flexible production systems that can easily adapt to changes in demand or product design. Robots can quickly switch between tasks, adjust settings, and modify the assembly process without major downtime, making them suitable for producing a wide range of products in smaller batches.

5. Precision and Quality Control

The high level of precision that robots offer is a significant advantage in ensuring the quality of products. Robots equipped with advanced sensors, cameras, and AI can perform real-time quality inspections during production, identify defects, and make necessary adjustments. This reduces waste, minimizes errors, and ensures that the final product meets high standards.

6. Supply Chain and Logistics Optimization

Robots also play a crucial role in the logistics and supply chain aspect of Industry 4.0. Autonomous mobile robots (AMRs) and drones are used to move materials within factories, warehouses, and distribution centers. These robots can transport goods efficiently and safely, ensuring that materials are always available where needed and reducing the reliance on human labor for material handling.

7. Predictive Maintenance

Robots equipped with sensors and connected to predictive maintenance systems can monitor the condition of machinery and production lines in real time. They can detect potential faults or wear and tear before they result in costly breakdowns, allowing for maintenance to be performed proactively. This minimizes downtime and extends the life of equipment.

8. Integration with AI and Machine Learning

The integration of robotics with artificial intelligence (AI) and machine learning technologies enhances their capabilities. AI can enable robots to perform more complex tasks, adapt to changing environments, and make decisions autonomously. Machine learning allows robots to optimize their operations by learning from experience and continuously improving their performance.

9. Human Augmentation

Robots in Industry 4.0 can also augment human capabilities by providing physical support or enhancing human cognitive abilities. For instance, exoskeletons (robotic suits) can help workers lift heavy objects, reducing strain and preventing injury. In addition, robots integrated with augmented reality (AR) can assist workers by providing them with real-time information and guidance during complex tasks.

10. Cost Reduction and Efficiency

By incorporating robotics into production processes, companies can achieve higher levels of efficiency, precision, and speed, all of which contribute to cost reduction. Robots can operate continuously without breaks, reducing labor costs and enabling production 24/7. Furthermore, they can streamline supply chains and logistics, cutting down on wasted time and resources.

In summary:

Robotics in Industry 4.0 is revolutionizing the way businesses operate by enhancing automation, flexibility, precision, and real-time decision-making. Robots not only take over repetitive tasks but also work alongside humans, enhancing their productivity and safety. The combination of robotics with other Industry 4.0 technologies like AI, IoT, and machine learning is creating smarter, more efficient, and more adaptive industrial environments.

- Get link

- X

- Other Apps

Comments

Post a Comment